In general, the concept of slipware refers to a technique used in the art of ceramics. It involves covering the surface of a terracotta (raw or fired clay) with a layer of diluted or colored clay, known as slip. This thin layer of clay can be applied before or after firing, depending on the desired techniques and effects. The main goal of slip is to add color, texture, or other decorative effects to the terracotta artifact. The artist or ceramist can create a wide range of colors by mixing pigments or oxides with the clay to achieve different shades. Additionally, slip can be used to create designs, patterns, or textures on the surface of the pot, adding a decorative or artistic element. In summary, slip allows for the customization and decoration of terracotta artifacts, enabling artists to express their creativity and achieve diversified aesthetic results.

To achieve a colored effect, the artisan must apply the slip layer at the right moment. The clay should not be too soft, as the coating could take on the color of the underlying clay, nor too dry, as it may not adhere properly.

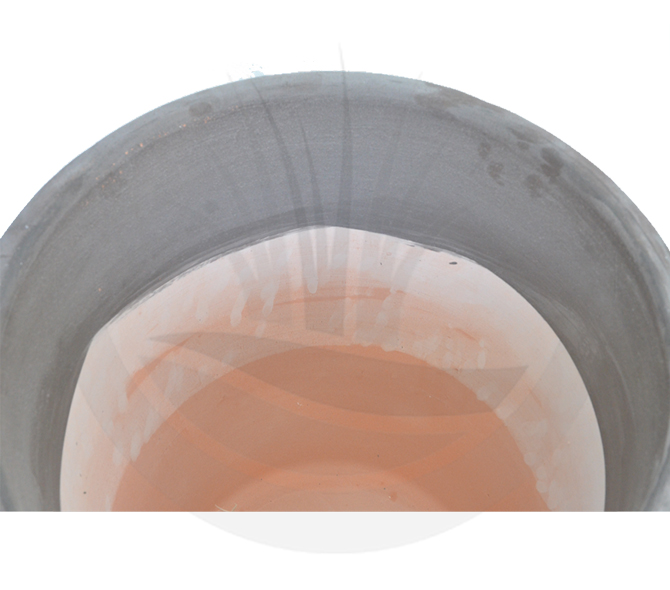

In our production context, Tuscan clay is typically of a red or pinkish color. With the application of slip during the finishing phase of the product, the vase can be colored, achieving a result similar to using a fully colored mixture. Normally, neither the interior nor the bottom of the vase is slip-coated; the former because it will contain the plant, and the latter because slip application must occur when the clay of the vase is still fresh. It becomes difficult to upside down the piece without damaging it, especially if it is of large dimensions.

With slipware or engobe, it refers to a coloring technique (but not only) of a terracotta pot by applying a layer of more liquid clay, called slip, on the object still to be baked. It is a hot process, in some respects similar to ceramics, with the aim of giving a different finish/coloration to the underlying pot

The use of engobe provides the manufacturer with greater flexibility, allowing them to enrich their catalog with a wider range of options at a lower cost. Managing production and orders with different clay mixtures can be complex, so engobe represents a convenient solution. Although the price of an engobed pot is lower than that of a colored mixture, it slightly compromises quality. Indeed, engobe forms a layer of clay applied over the underlying clay object and, despite the expertise of artisans, it may detach, especially due to impacts or particularly harsh weather conditions. This does not compromise the structure of the pot, but it may expose the red color of the underlying terracotta.

In the image, we can observe the interior of the vase, which, as mentioned, has not been engobed. The underlying color of the terracotta is visible, allowing us to appreciate the coating layer. The same situation will occur for the bottom of the vase.